Related news by tag Electron Microscopy

CIC nanoGUNE to expand its Electron-Microscopy facility with a unique FIB instrument

One of nanoGUNE's objectives in acquiring this equipment is to promote its widespread and large-scale use by the scientific community. Ikerbasque Professor Andrey Chuvilin, leader of nanoGUNE’s Electron Microscopy Laboratory, explains that “the success of the proposal is the result of a joint activity and accounts for the interests of diverse research centers: CIC bioGUNE, CIC energiGUNE, CIC nanoGUNE, and others”. This will be a facility opened for a broad community including industry interested in battery research, metals, and novel alloys.

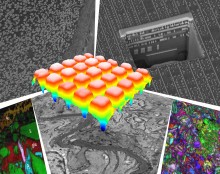

Evgenii Modin's "Microprocessor hieroglyphs", selected photo in FOTCIENCIA

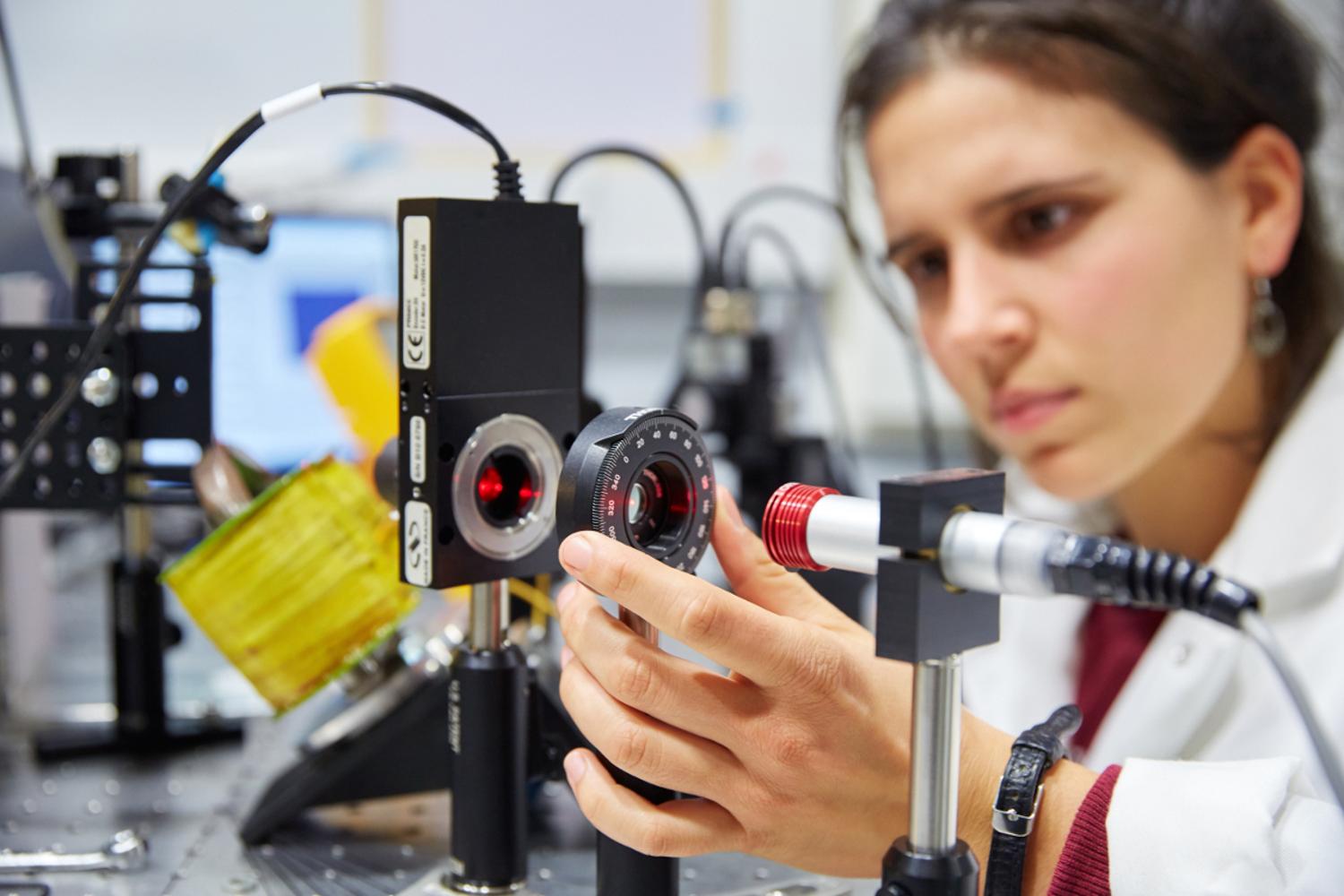

Evgenii Modin is a doctor in Physics currently working as Electron Microscopy specialist at CIC nanoGUNE. With the objective of giving as much visibility as possible to the science and the research capabilities of the Electron Microscopy Laboratory at nanoGUNE, Modin frequently publishes images related to his work through social networks, especially through the account @electronmicrolab on Instragram.

Registration period for the summer internship program open

CIC nanoGUNE has just launched the program for summer internships, which runs every year. University students are offered the chance to get involved in the activity of a world-class research center.

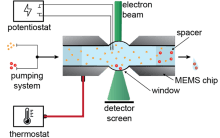

A nanofabrication instrument installed at nanoGUNE enhances the Basque electron microscopy infrastructure

The CRYO Plasma FIB is a unique advanced nanofabrication and electron microscopy instrument, one of the few in Europe; it will be supporting research centers and industry in the Basque Country and around the world in fields such as materials science relating to low temperature physics, lithium-ion batteries for the energy sector, and cryogenic electron cell tomography.

nanoGUNE Scholarship: call for Master Thesis students

The Scholarships will be of a total amount of 3,000€. This amount is for the whole period and will not be compatible with any other grant or funding awarded for the same purpose. Candidates have to be pre-registered and accepted at the above mentioned Master degrees in order to be eligible for these grants. Interested candidates can find all the information about the offered master projects and the application process following this link.

Besides the grants, nanoGUNE offers Master students coming from any official Master degree the possibility to develop their Master Thesis within one of its research groups.

Liquid-Phase Electron Microscopy Research with Economic Impact

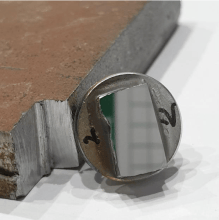

The first nanometrically-sized superelastic alloy

Superelasticity is a physical property by which it is possible to deform a material to a considerable extent, up to 10%, which is much higher than that of elasticity. So when stress is applied to a straight rod, the rod can form a U-shape and when the stress applied is removed, the rod fully regains its original shape. Although this has been amply proven in macroscopic materials, "until now no one had been able to explore these superelasticity properties in micrometric and nanometric sizes," explained José María San Juan, lead researcher of the article and a UPV/EHU professor.

The researchers have managed to see that "the superelastic effect is maintained in really small devices in a copper-aluminium-nickel alloy". It is an alloy with shape memory on which the research team has been working for over 20 years on a macroscopic level: Cu-14Al-4Ni, an alloy that displays superelasticity in ambient temperature.

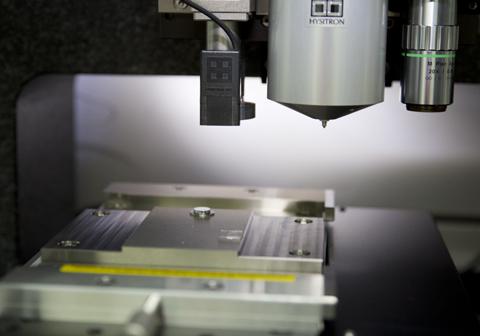

By using a piece of equipment known as a Focused Ion Beam, "an ion cannon that acts as a kind of atomic knife that shears the material", explained San Juan, they built micropillars and nanopillars of this alloy with diameters ranging between 2 μm and 260 nm --a micrometre is one millionth of a metre and a nanometre one thousand-millionth of a metre--. And to them they applied a stress using a sophisticated instrument known as a nanoindenter, which "allows extremely small forces to be applied," and then they measured their behaviour.

The researchers have for the first time confirmed and quantified that in diameters of less than a micrometre there is a considerable change in the properties relating to the critical stress for superelasticity. "The material starts to behave differently and needs a much higher stress for this to take place. The alloy continues to display superelasticity but for much higher stresses". San Juan highlights the novelty of this increase in critical stress linked to size, and also stresses that they have been able to explain the reason for this change in behaviour: "We have proposed an atomic model that allows one to understand why and how the atomic structure of these pillars changes when a stress is applied".

Microsystems involving flexible electronics and devices that can be implanted in the human body

The UPV/EHU professor highlighted the importance of this discovery, "spectacular superelastic behaviour on a small scale", which opens up new channels in the design of strategies for applying alloys with shape memory to develop flexible microsystems and electromechanical nanosystems. "Flexible electronics is very much present on today's market, it is being increasingly used in garments, sports footwear, in various displays, etc." He also affirmed that all this is of crucial importance in developing smart healthcare devices of the Lab-on-a-chip type that can be implanted into the human body. "It will be possible to build tiny micropumps or microactuators that can be implanted on a chip, and which will allow a substance to be released and regulated inside the human body for a range of medical treatments." It is a discovery that "is expected to have great scientific and technological repercussions and offer the potential to revolutionise various aspects in related fields," concluded San Juan.

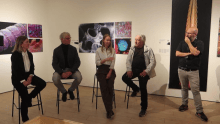

The hidden beauty of marine life revealed in the ITSASAMPLE exhibition

In this exhibition, electron microscopy, a cutting-edge tool in scientific research in the understanding of matter, plays a crucial role, since these microscopes are the eyes and hands of the research teams, enabling them to reveal, in this case, the features hidden from the naked eye of the samples provided by the Aquarium of Donostia / San Sebastian. The Plentzia Marine Station (PiE-UPV/EHU-University of the Basque Country) has also participated in the analysis of the images by helping to interpret the information provided by the microscope images.

Students from UPV / EHU, Tecnun, UAB and the UB carry out summer internships at CIC nanoGUNE

On Tuesday, 19 June, we welcomed a group of internship students that will carry out a research project at NanoGUNE during the summer. The director of the center, Jose M. Pitarke, received the students with a presentation talk about nanoGUNE, that was also attended by the researchers that will conduct the students’ projects.

The 11 students come from different universities, among which are, Unibersity of the Basque Country (UPV /EHU), Tecnun, Univeristy of Barcelona (UB), Autonomous University of Barcelona (UAB). This program offers to the students a real experience of work in a research laboratory in order to make it easier for them to take decision about their future professional life.

The students will collaborate and learn with the different research groups at nanoGUNE, such as nanooptics, nanodevices or nanomagnetism. They will carry out a research project for two months following the instructions of a researcher of their group.

Some of them started the internships at the beginning of the month and they have been very involved in the group’s work. "The truth is that we started very suddenly; the very first day they took me to the laboratory," says Amaia Ochandorena, a student of Biochemistry and Molecular Biology at the UPV/EHU.

All the students knew CIC nanoGUNE and stressed that "it is an important research center" and "offers and works with topics of much interest".

For these students, and also for undergraduate students of general, nanoGUNE offers the possibility of collaborating with the center for the completion of final graduate or master thesis projects, for which also opens a call for grants every year.

nanoGUNE launches a new summer internship call for university students

Through this programme the Basque nanoscience research centre will this summer be receiving about ten new students in their 3rd and 4th years of Physics, Chemistry, Biology and Engineering. For a period of six weeks or two months the young students will be collaborating with nanoGUNE researchers in their research projects on subjects such as electron/spin phenomena and magnetism, nanoscale optics, nanoscale materials and nanobioengineering, among others.

To participate in the summer internship programme any students who are interested will need to submit their applications online via the nanoGUNE website, the deadline being 16 February. Full information relating to the call is available via the nanoGUNE website (www.nanogune.eu)

CIC nanoGUNE and Astilleros Balenciaga collaborate to analyze marine-grade steel

To form steel sheet, the heat-based forming technique can be used; a heat source is applied followed by a cooling source in a specific way in order to produce a series of dilatations and contractions in the component whereby the sheet is gradually shaped. This process is carried out manually by applying the heat with a blowtorch and then applying cold water for cooling down purposes. Correctly applying the heat and cooling medium is decisive to ensure that the process takes place correctly and the desired shapes are obtained, while preventing the deterioration of the mechanical characteristics of the material used. Today, there is no data available confirming that this process, applied at all shipyards across the world, leads to a deterioration in the mechanical properties of the material.

That is why nanoGUNE’s Electron Microscopy group has analyzed steel samples provided by the R&D department of Astilleros Balenciaga. The study established that the heating process they apply to their metal sheet so that it can be molded does not lead to any detrimental change in the microstructure of the steel, which would result in a loss of mechanical properties of the component. By contrast, the results of the analysis show that some of the properties of the steel (yield strength directionality, ductility and resistance) improve as a result of heat treatment while defects and internal stress of the sheets are reduced, which leads to greater corrosion resistance.

These early results are opening up a very promising field in the analysis of heat formed components which both companies hope will lead to collaboration going forward to improve manufacturing processes in the metal industry.

Advances in Engineering: Microstructural aspects of metal cutting

The work focuses on the microstructural aspects that characterize the chip generation during metal cutting in two different scenarios defined by two different deformation mechanisms. This research sums up inputs from fundamentals of physics and from manufacturing techniques to explain a transition in material behavior which has not be explained previously, and which establishes new methodologies for future enhancements in metal manufacturing.

Journal article: Microstructural aspects of the transition between two regimes in orthogonal cutting of AISI 1045 steel